1

/

de

5

Raindew Official Store

10Pcs F605ZZ Flange Bearing 5X14X5 mm 3D Printers Parts

10Pcs F605ZZ Flange Bearing 5X14X5 mm 3D Printers Parts

Preço normal

$15.71 USD

Preço normal

$0.00 USD

Preço promocional

$15.71 USD

Preço unitário

/

por

Não foi possível carregar a disponibilidade de retirada.

Specifications:

Item: F605ZZ

Structure: Deep Groove

Bearing Material: Bearing Steel

Ball Material: Bearing Steel

Bore Dia (d): 5 mm

Outer Dia (D): 14 mm

Width (B): 5 mm

Closures: ZZ

Magnetic: little

Hardness: 58HRC

Corrosion Resistance: General

Clearance: C0

Bearing Grades: ABEC-7

Features:

Engineered for the VORON Ecosystem: Where Precision Meets Reliability

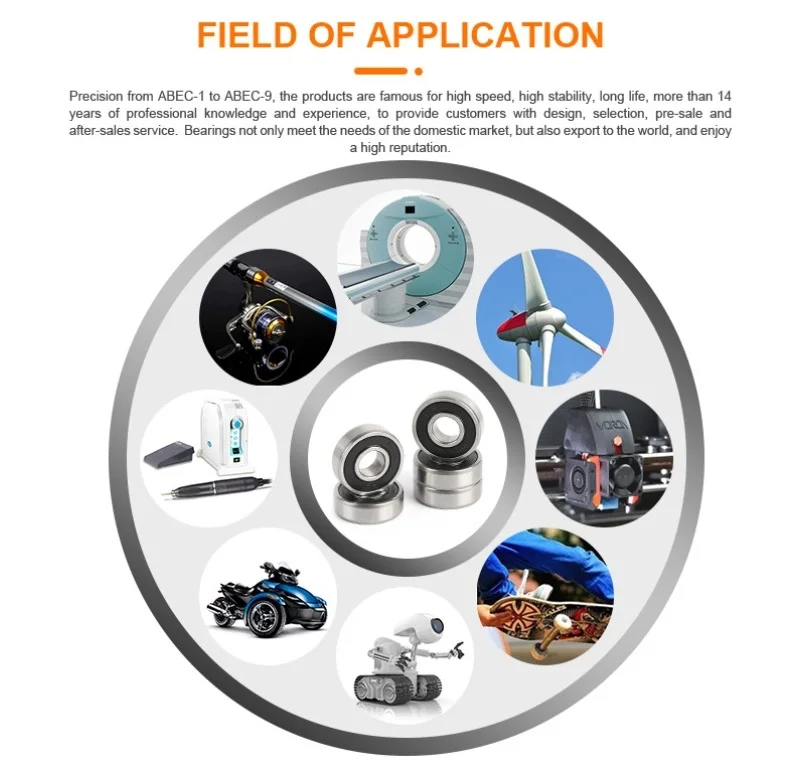

In high-speed CoreXY and Delta printing, stability isn't an option—it's the foundation of every clean layer. This precision flanged bearing is designed from the ground up for the demanding reality of VORON builds, eliminating the microscopic vibrations and alignment drift that undermine print quality at extreme speeds. It delivers the industrial-grade motion control required for rock-solid toolhead paths, reliable belt transmission, and sustained accuracy through marathon print sessions.

Built for the VORON Doctrine of Performance

✅ Sealed Against the Print Environment

A multi-defense sealing architecture locks out fine ABS/ASA dust and synthetic fiber debris, protecting critical internals in enclosed chamber environments. Formulated high-temperature grease maintains consistent viscosity to resist thinning near heated chambers, ensuring long-term smooth rotation.

✅ Precision-Tuned for High-Speed Motion

Ultra-smooth raceways and precision-grade elements are matched to eliminate stiction and rotational inconsistency—key for flawless micro-movements during complex pressure advance and input shaping routines. This results in quieter operation and the elimination of bearing-induced artifacts on finished surfaces.

✅ Flange-Enforced System Integrity

The integrated flange provides positive mounting and permanent pulley alignment, critical for maintaining precise belt path geometry in constrained gantry designs. This directly counters the root causes of layer shifts and inconsistent extrusion in dynamic CoreXY kinematics.

✅ Validated for Demanding Duty Cycles

Rigorously tested under continuous high-speed printing, rapid directional changes, and the sustained thermal exposure of an active heated chamber. Engineered to perform consistently from the first layer to the last in extended, high-temperature builds.

The Bearing Built for the Demanding VORON Platform

Specifically developed for critical motion points: idlers on X and Y axes, extruder drive assemblies, and any pulley location where precision and longevity are non-negotiable. It is the chosen component for builders who prioritize dimensional accuracy, reliability for thousand-hour print runs, and uncompromising performance in pursuit of the perfect print.

Share