1

/

von

6

Raindew Official Store

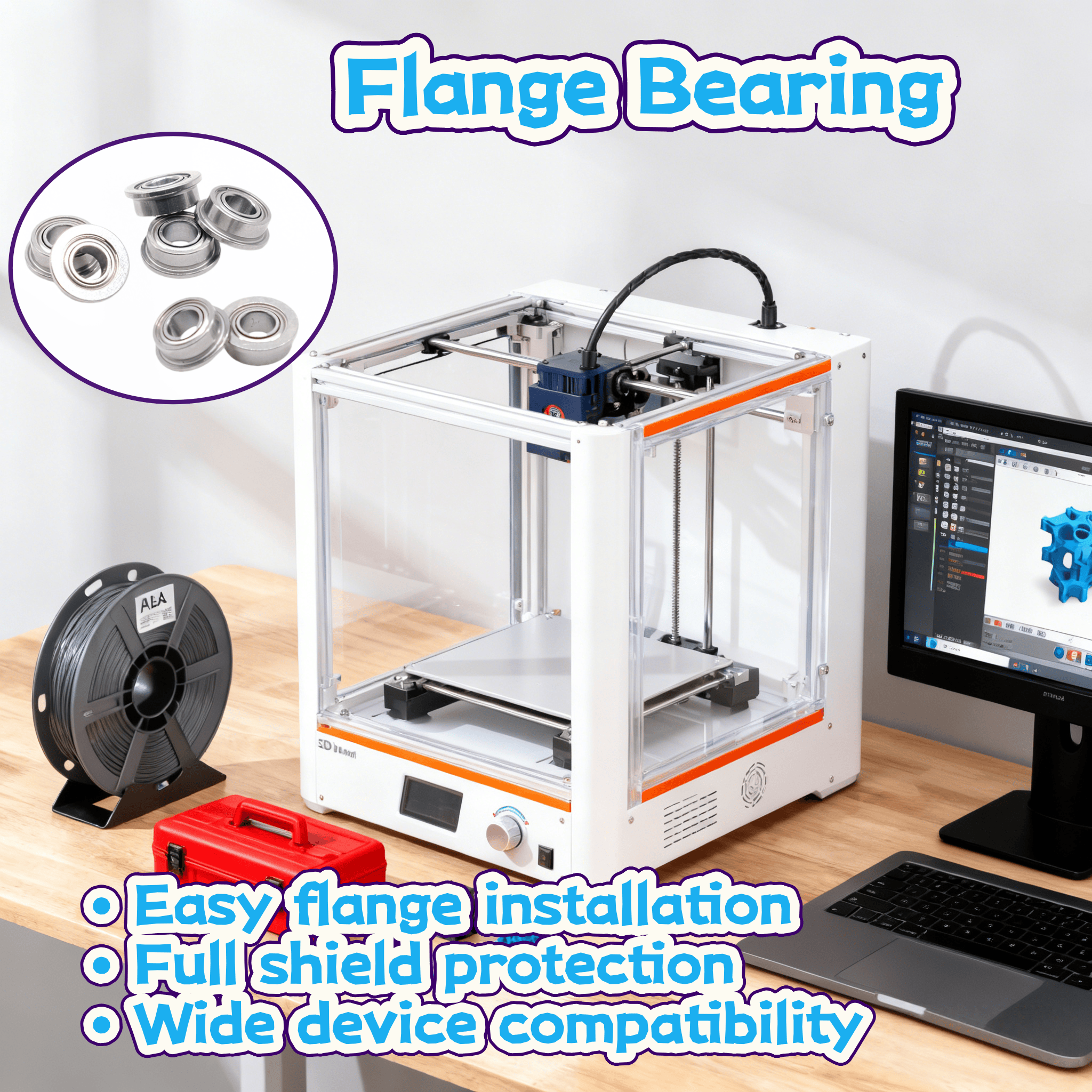

10PCS MF106ZZ Flanged Ball Bearings 6X10X3 mm Steel Shielded for 3D Printer & Stepper Motor

10PCS MF106ZZ Flanged Ball Bearings 6X10X3 mm Steel Shielded for 3D Printer & Stepper Motor

Normaler Preis

$16.07 USD

Normaler Preis

$0.00 USD

Verkaufspreis

$16.07 USD

Grundpreis

/

pro

Verfügbarkeit für Abholungen konnte nicht geladen werden

Specifications:

Item:MF106ZZ

Structure: Deep Groove

Material: Chrome Steel

Bore Dia (d): 6mm

Outer Dia (D): 10mm

Width (B): 3mm

Closures: Metal Shielded

Lubrication: Grease

Magnetic: little

Hardness: 58HRC

Corrosion Resistance: General

Clearance: C0

Grades: ABEC-9

Features:

Engineered for Structural Integrity in Space-Constrained Applications

Designed to withstand rigorous operating conditions where radial space is limited, this flanged bearing establishes a new standard for reliability in compact mechanical systems. The integral flange creates a secure interface with mounting surfaces, delivering exceptional resistance to axial displacement while maintaining perfect shaft alignment. Manufactured with rigorous tolerance controls, it demonstrates outstanding durability under complex loading scenarios, providing extended service life in applications where conventional thin-section bearings would typically deteriorate prematurely.

Advanced Engineering for Demanding Environments

✅ Multi-stage sealing system with integrated contact and labyrinth barriers provides complete protection against dust, moisture, and other contaminants while maintaining low torque characteristics

✅ Precision-hardened stainless steel raceways and high-grade bearing balls ensure smooth rotation with minimal vibration and acoustic emissions

✅ Optimized flange geometry offers enhanced mounting stability while maximizing space efficiency in compact designs

✅ Specially engineered cage design and advanced lubrication system enable reliable high-speed operation across various temperature conditions

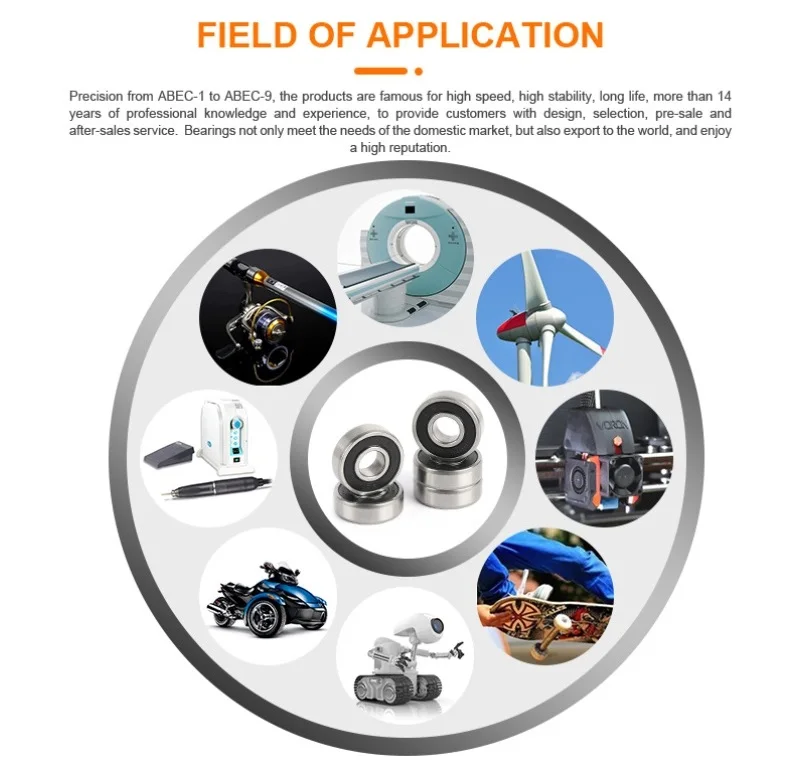

Verified for Critical Industrial Applications

Ideal for precision motors, medical equipment, industrial automation, and aerospace mechanisms where reliability and precision are paramount. Each unit undergoes rigorous testing for rotational accuracy, torque consistency, and environmental durability, ensuring compliance with stringent industry standards for demanding applications.

Share